Die Makers Handbook Pdf

Jan 11, 2007 - The word “die” in itself means the complete press tool in its entirety, with all the punches. Yet, for some reason, today's manufacturers often. The Die Makers Handbook is a must-have for your toolbox, desk, or briefcase. Developed from more than 30 years of practical shop-learned information. Developed from more than 30 years of practical shop-learned information.

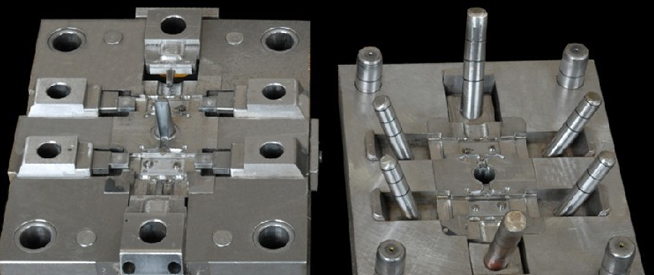

COMPETENCE IN TOOL AND DIE MAKING Step by step to more productivity EROWA palletizing and clamping systems provide the interface between the workpiece, fixture and machine. They are crucial for efficient, flexible and competitive manufacturing. Palletizing of workpieces opens up many ways to make your production more productive step by step. Complete electrode manufacturing - milling, drilling, turning.

HSC milling on fully integrated PowerChuck P. Coordinate grinding with maximum precision starting already with the clamping system. Surface and profile grinding - stable, waterproof and corrosion-resistant. COMPETENCE IN TOOL AND DIE MAKING EROWA UPC PALLETIZING SYSTEM Universal palletizing system: UPC chucks as an interface to the workpiece carrier in an EROWA RoboSPA cleaning and drying module.

• Blow-off Z-supporting surfaces. • Pallets 4 x 90° indexable. • Repeatability. COMPETENCE IN TOOL AND DIE MAKING EROWA UPC PALLETIZING SYSTEM The UPC chuck with the integrated ITS chuck ensures seamless integration of EROWA ITS 50 or ITS 100 workpiece carrier in the UPC system. This combination enables the flexible use of the clamping system depending on the part size. Vices, gauges and fixtures are mounted on the UPC pallet.

We will be happy to advise you on customized fixture solutions as well. The UPC palletizing system is the interface between the manufacturing machine and the workpiece for various machining technologies such as: milling, grinding, EDM sinking and measuring.

COMPETENCE IN TOOL AND DIE MAKING EROWA CLAMPSET CLAMPING SYSTEM Palletized ClampSet vise on UPC grid pallet. The EROWA UPC palletizing system is the seamless interface between the machine and the ClampSet workpiece carrier for a wide variety of machining technologies. ClampSet product overview • Wide choice of various precise clamping elements. • Easy installation on EROWA palletizing systems. • All components made of hardened and ground steel. • Different clamping jaws to accommodate various workpiece shapes.

• Clamping range up to 225 mm. • Can be used vertically and horizontally. • Once palletized. COMPETENCE IN TOOL AND DIE MAKING EROWA CLAMPSET CLAMPING SYSTEM ClampSet multi-clamping on a UPC clamping cube for horizontal machining. ClampSet vise on ITS pallet.

Positioned with micron precision and ready for use in seconds. With ClampSet vices, even long or large workpieces can be clamped easily. The convenient prism jaw for clamping several cylindrical parts in horizontal or vertical position.

By setting up and adjusting the workpieces outside the machine, time can be optimally used and cost can be reduced. COMPETENCE IN TOOL AND DIE MAKING EROWA POWERCHUCK P PALLETIZING SYSTEM PowerChucks are the basis on the machine table. Fixtures are mounted on ITS pallets. Workpieces are prepared during production time. PowerChuck P product overview • Blow-off Z-supporting surfaces. • Pallets 4 x 90° indexable. • Repeatability.

It features two dual-link DVI-I port; each port can drive a 2560 x 1600 digital display.  Dual Monitor The video card can drive dual monitors. Windows Vista Support This card is fully compatible with Microsoft's Windows Vista operating system.

Dual Monitor The video card can drive dual monitors. Windows Vista Support This card is fully compatible with Microsoft's Windows Vista operating system.